-

2 27 2023How many jin of cotton lint can be produced per ton of wool cotton seed

First of all, let's understand that one ton is 2000 catties, and the wool cotton seed is divided into sawtooth cotton and roller cotton. Here we will only talk about the wool cotton seed of sawtooth cotton. Then distinguish the cottonseed in the local area and the wool cottonseed in Xinjiang. The wool yield of the wool cottonseed in the local area is 12-13%. The lint yield of wool cotton seeds in Xinjiang is generally 13-14%. I'm talking about high probability events. Because the years are different, the data will be different. But this is generally the case. It is about 120-130 pounds for real estate and 130-140 pounds for Xinjiang.

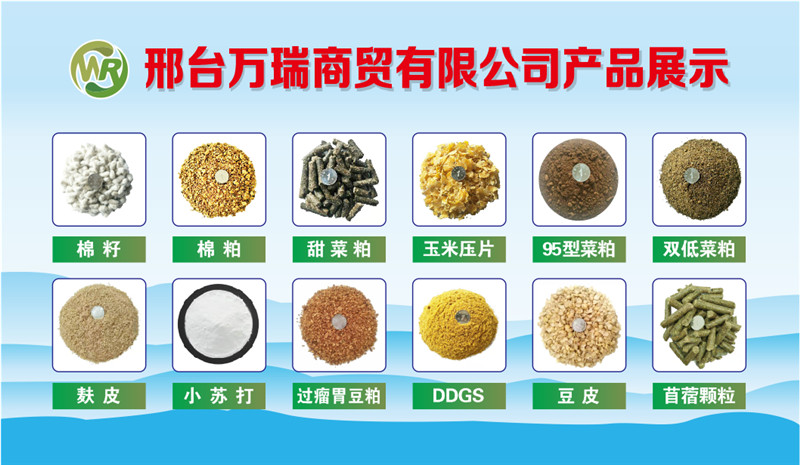

Xingtai Wanrui Trading Co., Ltd. operates and sells: beet meal granules, beet meal granules, direct supply of beet meal manufacturers, beet meal prices, double-low rapeseed meal feed, cottonseed meal wholesale manufacturers, cottonseed shell wholesale, Xinjiang wool cottonseed meal, DDGS protein feed, DDGS feed wholesale manufacturers, corn DDGS feed, steam flaked corn, steam corn flaked price, flaked corn manufacturers, tea residue feed, turmeric residue feed Ginger powder for cattle and sheep, chrysanthemum powder for feed, chicken fermented feed bacterial residue, high-quality fermented feed bacterial residue, pepper meal wholesale manufacturer, pepper oil residue manufacturer wholesale price, feed-grade malt root, malt root manufacturer, beer lees protein feed.

-

1 7 2023Nutritional characteristics of corn germ meal

Corn germ meal contains 18% ~ 20% crude protein, 1% ~ 2% crude fat and 11% ~ 12% crude fiber. Its amino acid composition is similar to corn protein feed (or corn gluten feed). Although the name belongs to the category of cake and meal, according to the international feed classification, most products belong to the middle grade energy feed. From the perspective of protein quality, although the protein quality of corn germ meal is higher than that of cereal energy feed, the content of various restricted amino acids is lower than that of corn gluten meal, cotton and rapeseed meal.

The content of crude protein and crude fiber in dry corn germ meal was lower than that in wet corn germ meal, and their effective energy values were similar. The content of minerals and trace elements varies with processing technology.

-

1 7 2023What is the effect of feeding corn germ cake to cattle?

It is no problem to feed corn germ cake to cattle. It can be said that it is the protein energy feed with the highest cost performance ratio. The crude protein of corn germ cake is 18-24%, the crude fiber is about 6%, the fat is 8-10%, and the dry basis is more than 25%; It is more suitable for ruminants to eat, and corn germ cake has higher cost performance ratio than soybean meal, and has higher advantages.

However, most farmers have a low understanding of corn germ cake. At present, large farmers mainly use corn germ cake!

-

12 6 2022The bark of the almond tree can be fed to lactating cows in large quantities

-

12 6 2022Utilization of beet meal

Sugarbeet residue is a by-product of sugar production. It is the residue of sugar beet root and tuber after soaking and pressing to extract sugar solution. Therefore, there are a lot of water-insoluble substances in the residue, especially crude fiber. It is a good juicy feed for livestock. It can also promote lactation for female livestock, and is mainly used for feeding cattle. The main ingredients are soluble nitrogen free substances, but there is little protein and fat. There is very much calcium and little phosphorus, which is palatable and contains more crude fiber.

1. The wet beet residue should not be fed too much and should be mixed with protein feed or other green feed, such as soybean cake, corn, wheat bran, hay, silage, carrots, etc. The recommended feeding amount should not exceed 10% of the ration: 1.50-3.50 kg/day · pig, 2.50-3.50 kg/day · sheep. Cows can be fed 12kg a day, and young bulls can be fed 24kg Beef cattle 30-40kg/day. Pigs shall be fermented and fed only to fattening pigs and lactating sows. For ruminants, wet meal can be fed directly. Dry cypress can replace about 30% of cereals in the diet. It can be mixed with concentrate after soaking or fed alone

In the whole concentrate H grain for fattening pigs, beet residue was used to replace 15% corn (LW=35~60kg) and 25% corn (LW=60~90kg), which did not affect the weight gain, reduced the cost, improved the carcass quality, and increased the lean meat percentage. The use of beet residue instead of cereal feed (barley) in the diet of Holstein cows in the late lactation period did not affect the milk yield of milk protein and lactose, increased the milk fat rate and energy level, and decreased the plasma glucose and cholesterol content. This is because beet residue contains high neutral detergent fiber pectin, niacin and betaine.

2. Silage of beet residue

The fattening pigs (LW=34~144kg) could not affect the growth and slaughter performance of pigs by replacing barley with silage beet residue added with liquor tank. Therefore, silage beet residue can be used to save grain feed.

In order to improve the quality of silage, the addition of absorbent (grain, corn stalk soil, polyacrylamide) can reduce nutrient loss. China is rich in crop straw, which is a good absorbent resource. Adding absorbent during silage can reduce the loss rate of soluble sugar, increase the content of dry matter, acid detergent fiber and crude protein, reduce the content of neutral detergent fiber, and effectively reduce butyric acid fermentation. Urea 4g/kg and 6g/kg (nitrogen content 46%) can also be added to reduce the pH value. Ammonia nitrogen, crude protein and soluble sugar content increased significantly, and butyric acid production was inhibited. 0.034% - 0.064% molasses silage can also be added, which can improve the feed conversion efficiency and dry matter intake of goats. The reason is that the beet residue has good palatability. After adding honey silage, the nutrient content is increased, and the dry matter content can reach 847g/kg Crude white matter is 115g/kg, and soluble sugar content can reach 270g/kg.

3. Mixed silage of sweet rice dregs

Adding crop by-products (rice straw, corn straw, bean pod and bran) can make the talent content reach 70%, improve the silage quality of beet residue, reduce ammonia nitrogen, and increase the content of dry matter, crude protein and soluble sugar. It is suggested that 10% - 20% crushed dry rice straw should be added to the beet residue silage. The second is dry bean pods, which crush thousands of corn stalks and bran. Mixed silage can make nutrients complementary and prolong the storage time.

4. Sugar beet residue granulated meal

After the granules are made, the moisture content is reduced, the transportation is convenient, and the preservation is beneficial. Sugarbeet dregs can further improve the utilization rate of nutrients, improve feed returns, eliminate anti nutritional factors, avoid animal pickiness, ensure the full price of feed and facilitate feeding through the effects of high temperature steam, pressure and other factors in the pelleting process The artificial feeding is reduced, and the feeding time is 1/3 of the powder, which reduces the consumption of feeding activities of high poultry and the natural loss of feed.

Beet meal was used to replace 15% - 40% (energy feed (corn) with wide dry matter basis) in the diet of dairy cows It can increase the feed conversion rate, milk fat rate and milk protein rate, reduce the risk of rumen acidosis, hoof disease and heat stress, buffer the rumen pH value, and improve the rumen function. These functions are derived from the rich soluble fiber and pectin in beet residue.

5. Other values of beet residue

The American Helette Aquaculture Research Institute also introduced the use of beet residue as a cheap shrimp bait. Sugarbeet residue can be used to prepare oxalic acid, cellulose and pectin. The beet residue also has the function of reducing blood lipid, and can be developed as a health product.

The yield of beet is huge, and the nutritional value of beet residue has been widely recognized by researchers. In addition to the pressure of grain shortage, beet residue has become a potential feed resource with development value.

6. The value of betaine

Beet meal is rich in betaine. As a methyl donor, betaine has similar nutritional effects with methionine and choline, and has the functions of improving the production performance of cows and sows, regulating lipid metabolism, etc.

By promoting the synthesis of phospholipids in the body, betaine, on the one hand, reduces the activity of fat synthase in the liver, on the other hand, promotes the synthesis of apolipoprotein in the liver, promotes the migration of fat in the liver, reduces the content of triglycerides in the liver, and effectively prevents the accumulation of fat in the liver. It can reduce the deposition of body fat by promoting the decomposition of fat and inhibiting the synthesis of fat. Betaine has a significant effect on reducing the liver fat content of grass carp. When grass carp are fed with formulated feed for a long time without green feed supplement, adding betaine can effectively prevent fatty liver disease caused by nutrient deficiency.

-

10 24 2022The corn tablet manufacturer explains the advantages and disadvantages of feed identification skills

All plant, animal and mineral substances that can supply livestock and poultry to feed, digest and absorb nutrients and have harmless effects are collectively referred to as feeds. As the saying goes, "Food is the most important thing for people and material is the most important thing for livestock". Feed can not only maintain the life of livestock and poultry, but also determine the productivity of animal husbandry. Only qualified feed can ensure the healthy growth of livestock and poultry. The current corn flake manufacturer introduces the identification methods of good and bad feed as follows for the reference of the majority of farmers.

1. Look at the trademark.

For the feed produced by regular manufacturers, the product package has a label approval certificate number, a label code, and a trademark registered by the industry and commerce department. The top right of the registered trademark is printed with the "R" sign, and the package is beautiful and tidy, with clear factory address and telephone. The package of fake and inferior feed is rough. The factory address and telephone number on it are false, and there is no registered trademark.

2. Look at the date.

The breeder shall purchase the feed within the shelf life to feed the livestock and poultry. After the shelf life, the feed will inevitably deteriorate. Even if it is well preserved, the content of vitamins and other nutrients in the feed will decrease after oxidation, affecting the feeding effect. In addition, the feedstuff purchased by farmers should also be fed within the shelf life.

3. Look at the color.

Check whether the color of the feed is consistent, whether it contains impurities, and whether the raw materials are mixed evenly. When purchasing the same brand of feed, attention should also be paid to the large change in color of successive batches of feed. The general feed color is yellow, indicating that the proportion of corn and soybean meal is large; When the color is dark, the proportion of fish meal and rapeseed meal is large.

4. Look at the particles.

The feed produced by regular feed manufacturers is well mixed, pelleted and cooled, so the feed surface is smooth and the particles are even. Poor quality feed is difficult to ensure the quality of feed granules due to the simple processing equipment.

5. Smell.

A good concentrated feed should have a pure fishy smell, without odor or other peculiar smell; The inferior feed has a putrid smell or essence smell (essence is added to cover the musty smell of deteriorated raw materials). Therefore, although some feedstuffs are particularly fragrant, they are not good feedstuffs. Good feedstuffs should have the flavor of soybean and corn.

6. Touch.

Grab a handful of feed and squeeze it with force. If it does not loosen, it indicates that the feed contains too much water, and it is easy to become moldy and deteriorated when stored; You can also insert your hand into the feed. If you feel the feed is hot, it indicates that the feed has started to mildew.

7. Listening.

When the fresh and dry feed is stirred, it is loose without caking, with good fluidity and clear sound; On the contrary, if the water content is high, the moldy and inferior feed will have no sound or dull sound.

-

10 24 2022What is extracted from corn tablets

Now many farmers choose to use corn flakes as feed for cattle and sheep. How can corn flakes be produced?

1. Corn flaking is the extraction of corn peptide, which is corn protein extracted from natural food corn. First, fully soak the corn that meets the standard, and then steam process the corn under the high temperature of 110-140 ℃ to puff and soften it, then peel and fracture the expanded corn, process the corn into thin slices of specified density, and then dry it.

2. The main functions of corn squashing process are water, heat, treatment time and mechanical action, which is a series of physical changes of corn starch.

3. Corn tableting can improve the gelatinization degree of corn, make starch soluble, and improve the consumption and absorption rate. Generally, corn tableting can improve the digestibility by 15-20%.

4. High temperature steam can sterilize and disinfect pressed corn, so that animal body can reduce disease.

-

9 27 2022Application of double bottom rapeseed meal in ruminants (e.g. cattle)

Studies have shown that double low rapeseed meal can promote gastrointestinal development of piglets compared with soybean meal.

Application of double bottom rapeseed meal in ruminants:

Recent research shows that double low rapeseed meal can partially or completely replace most common protein feeds, such as soybean meal, cottonseed meal and brewer's grains, without affecting the production performance of cattle and sheep.

In some cases, it can improve the production performance and nitrogen utilization rate of dairy cows. Double low rapeseed meal significantly increased the milk yield of early lactating cows; The crude protein content of the whole mixed diet was 16%~18%, and no significant change was observed in lactation response. The feed efficiency of double bottomed rapeseed meal is often higher, and the urea nitrogen of milk is lower.

Based on in vitro and in vivo experiments, the substitution of double low rapeseed meal for soybean meal will not significantly change rumen fermentation, indicating that the advantages of double low rapeseed meal may be related to increased dry matter intake or better post rumen utilization efficiency, such as amino acid composition. It needs to be clarified that double low rapeseed meal has better production performance than soybean meal on ruminants. The reason may be that the difference of amino acid/essential amino acid donors is due to the amount of more rumen microbial protein flowing into the small intestine. Double low rapeseed meal can replace soybean meal, increase dry matter intake, milk yield and milk protein, and reduce rumen ammonia and urine nitrogen concentration.

The response of cattle and sheep to double low rapeseed meal also varied with the source of roughage. Double low rapeseed meal was better in the diet with alfalfa silage as the main source of roughage.

Feeding calf with this raw material has no obvious effect on its growth. This is because the soluble protein content in the double low rapeseed meal accounts for 20-25% of the total protein, the effective protein degradation rate is 60-70%, and the degradation rate in the rumen of cattle is 7-15%/h. Therefore, double low rapeseed meal can replace soybean meal or cotton meal as a separate protein supplement for dairy cattle feed or beef cattle feed. Double low rapeseed meal completely replaces the soybean meal in the calf starter feed, reducing the number of days of diarrhea for calves, and other growth performance is basically the same, but it has a slight impact on feed efficiency and nitrogen metabolism.

-

9 27 2022Steam flaking corn can effectively improve beef cattle production performance

Corn flake is made of corn by high-temperature steam treatment and pressing. It is a process of hot and humid processing of corn. It can improve the biological value of corn by changing the physical and chemical state of corn.

Steam flaked corn in Europe and America has been widely used in beef cattle and dairy cattle production. The method of direct feeding of steam flaked corn is widely used, which not only saves resources but also improves production efficiency.

Since the introduction of steam flaking technology and equipment in China, it needs to be further promoted, especially in the field of beef cattle production.

In addition to beef cattle, cows, mutton sheep, pigs and other livestock, corn flakes can also be used to feed hairy crabs, crayfish and other aquatic products.

Steam flaking corn can effectively improve beef cattle

Production performance:

After treatment, the pressed corn improved the total digestive tract absorption of starch, crude protein and dry matter. High temperature steam has bactericidal effect on raw corn grains, which can reduce animal diseases and prevent diarrhea. As the main energy feed for beef cattle, the digestibility and utilization of corn directly affect the production performance and meat quality of beef cattle. The unprocessed corn will affect the contact of microorganisms and enzymes with starch, thus hindering the digestion and utilization of starch by beef cattle. In order to effectively use corn, corn is usually processed before feeding.

Most beef cattle farmers think that the price of steam pressed corn is high, beef cattle breeding does not need to be as sophisticated as cow breeding, and meat can be grown with crushed corn, so they are unwilling to invest. However, we suggest that farmers use steam pressed corn instead of crushed corn, which can significantly improve the weight gain and feed returns of beef cattle, and the meat quality of the fed beef cattle is good.

Steam flaked corn vs. crushed corn

Advantages:

Compared with crushed corn, steam pressed corn can improve the digestibility of rumen starch of cattle by 24%, rumen bypass starch by 26%, and total digestive tract starch by 10%. The total digestive tract starch digestibility of steam pressed corn is 99.1%. In addition, the use of steam pressed corn can also promote the digestion and metabolism of other substances and reduce nitrogen and phosphorus emissions. Steam compression of corn increased the digestibility of nitrogen in small intestine and total intestine by 10% and 8%, respectively.

The relevant enterprises made a correlation comparison on the effect of steam pressed corn on the production performance of beef cattle during the fattening period. They selected 28 beef cattle with similar weight and randomly divided them into groups ①, ②, ③ and ④ for four months. Under the same conditions of concentrate, silage and distiller's grains, only the proportion of steam pressed corn in group ①, ②, ③ and ④ concentrate feed replacing ordinary broken corn was changed to 0%, 30%, 60% and 90% respectively. The research data showed that the daily weight gain of the four groups was 985.3 g, 1181.6 g, 1273.7 g and 1351.4 g respectively. The results showed that the daily weight gain of corn fed by tablet was the most obvious.

A large number of studies have shown that steam flaking is an effective method of corn processing, which can improve the production performance of beef cattle. The feeding method of steam flaking corn and the proportion of concentrate and coarse fodder in the diet should also be reasonably adjusted according to the beef cattle variety and growth cycle.

-

8 24 2022Nutritional value of palm meal to beef cattle

Palm meal is a by-product of palm kernel hulling and oil pressing. Its shape and color are similar to those of rapeseed meal, and its smell is slightly chocolate. The quality of palm kernel meal varies greatly depending on its hulling degree and processing technology (similar to that of cotton meal). The most direct manifestation of using palm kernel meal to replace some corn is that the feeding effect is unchanged, but the feed cost is greatly reduced, and the competitiveness of animal products in the same industry is significantly improved. However, it is about 400 yuan cheaper than corn per ton. With the rapid rise of corn prices in northern and Northern China and the long-term downturn of animal product prices, some large and medium-sized feed enterprises must do everything possible to reduce costs in order to survive. Therefore, the use of palm kernel meal instead of some corn has become the s-choice product.

Functional components of palm meal fermented by roughage degrading agent

Here Z it is worth mentioning that the oligosaccharides produced after the degradation of palm meal, such as low molecular mannan oligosaccharides, are low molecular products after the decomposition of mannan in the fermentation process of roughage degrading agent, and glucogalactooligosaccharides. These small molecular oligosaccharides can effectively improve the disease resistance of animals. The mechanism is: (1) it preemptively combines with pathogenic bacteria (bacteria with type 1 pili, such as Escherichia coli, Salmonella, Vibrio cholerae, etc.), Blocking the adhesion between the pathogen pili and the intestinal epithelial receptor, thus preventing the pathogen from colonizing in the intestine and eliminating its pathogenic effect; (2) As an immune regulator, it stimulates the host to produce non-specific immunity and enhances the disease resistance; (3) Do not provide nutrition for pathogenic bacteria, making them hungry and unable to survive; (4) It has a strong adsorption on mycotoxins, which can greatly reduce the immunosuppressive and toxic effects of mycotoxins in feed.

Method of feeding animals with degraded fermented palm meal

The protein content of the palm meal fermented by the above method is about 17%, the digestibility energy is about 2.7 megacalories / kg, and the metabolic energy is about 2.4 megacalories / kg. It is recommended that the amount used in the animal diet be 20-40%, the small value for young animals and the large value for adult animals. The specific feeding amount is subject to the observation in practice. If the animal adapts, the amount can be increased slowly, otherwise, the amount can be appropriately reduced.

-

8 24 2022The amount of cotton meal in different animal feed

The amount of cotton meal in different animal feed

1. Chicken feed

10% - 20% of the diet can be used in broilers, 5% - 15% of the diet can be used in laying hens, and the amount of meal without detoxification treatment in the diet should not exceed 5%.

2. Pig feed

Generally, suckling pigs and piglets do not need cotton meal, which can be used to 10% - 20% in the diet of adult pigs and 3% - 5% in sows.

3. Cattle feed

Cotton meal is a constipation feed raw material, which must be used with sesame meal and other soft feed raw materials. Generally, the feed consumption of dairy cattle should be 20% - 35% of the concentrate. When feeding fine cattle, it is appropriate to lower than 20% of the concentrate, and it should be matched with high-quality roughage with high carotene content. Beef cattle can generally account for 30% - 40% of the concentrate.

4. Sheep feed

The cotton meal used in the sheep feed should be mixed with high-quality concentrate, and the dosage should not exceed 50% of the concentrate.

When buying cotton meal, observe its color and shape. The sensory characteristics are small pieces or cakes, the color is fresh and consistent yellowish brown, the black fragment shaped cottonseed shell is less, the lint is less, and there is no mildew and caking. Hold a handful of cotton meal in your hand, carefully observe whether there is any doping, and estimate the proportion of cottonseed shell and the content of lint. If the content of cottonseed hull and lint is high, the quality of cottonseed meal is poor. Crude protein was lower and crude fiber was higher.

The moisture content shall not exceed 12%. Grasp a handful of cottonseed meal and loosen it. If the cottonseed meal is held in a lump, the water content is high; if it is loose, the water content is low. Pour the cotton meal and observe the hand residue. If there is more residue, the water content is higher, and vice versa. Feel the humidity of cotton meal with your hand. Generally, the temperature is high and the moisture is high. If you feel hot, a large number of piles are likely to spontaneous combustion.

Because cotton meal is highly likely to be infected with aflatoxin, it will cause slow growth when eaten by livestock and poultry, and aflatoxin test can be carried out when necessary.

-

7 26 2022Effect of soybean peel on ruminant growth

Soybean peel can be used as animal feed because it contains certain nutrients, which meets the needs of animal growth. However, different animals have different characteristics in physiology and growth habits, so the requirements for feed are different. The application effect of soybean peel in ruminant feed is very good, mainly because it adapts to the digestive characteristics of this animal and can better develop nutritional value.

Ruminants are some common herbivores in our life, such as sheep, cattle, etc. these animals have characteristics in digestion. After eating, the feed will be swallowed into the rumen without sufficient chewing, especially the roughage. In the rumen, the feed will be soaked and softened. After a period of time, the food will return to the mouth, chew again, and then mix saliva into the rumen.

The characteristics of soybean peel meet the digestion requirements of ruminants, because the digestibility of soybean peel is high and the digestion speed is fast. Moreover, soybean peel can promote the digestion of cellulose, because the digestibility of soybean peel cellulose is relatively high, which can stimulate the growth of microorganisms decomposing fiber in gastric juice and enhance the degradation activity of cellulose.

Moreover, the application of soybean peel can also reduce the metabolic diseases of ruminants, because cereal feed contains more starch, which is easy to ferment rapidly in the rumen, resulting in the decline of pH value of gastric juice and the disturbance of microflora, which will lead to the occurrence of acidosis, which will affect the digestion of feed. Using soybean peel, there is no starch, reduce acidosis, and ensure the black rumen pH value.

Therefore, the application of soybean peel can not only promote the digestion of feed, but also be good for the stomach of animals. Now, Shandong soybean peel manufacturers supply more and more soybean peel, and the quality is also very good, providing sufficient feed for animal growth.

-

7 26 2022Help animals digest and absorb -- corn tabletting

1、 What is extracted from corn chips

1. Corn Flake pressing is to extract corn peptide, which is corn protein extracted from natural food corn. First, fully soak the corn that meets the standard, then expand and soften the corn through steam processing at a high temperature of 110-140 ℃, then peel and fracture the expanded corn, process the corn into thin slices with specified density, and then dry it.

2. The main functions of Corn Flake pressing process are moisture, heat, treatment time and mechanical action, which are a series of physical changes of corn starch.

3. Corn Flake pressing can improve the gelatinization degree of corn, make starch soluble, and improve the consumption and absorption rate. Generally, Corn Flake pressing can improve the digestibility by 15-20%.

4. High temperature steam can sterilize and disinfect the pressed corn, reduce disease and prevent diarrhea.

2、 What are the benefits of corn tablet feeding

1. The digestibility of starch in the whole digestive tract after corn pressing is 95-100%. Feeding corn pressing can improve the palatability of pig feed, increase the daily gain of piglets by about 6%, and increase the daily gain of fattening pigs by about 2-3%.

2. Feeding cows with corn chips can increase milk production by 8-10%, and each cow produces about 2.4-3 kg of milk per day on average.

3. It can also be used under cold and heat stress of cows, which can improve the ability of cows to resist cold and heat stress, alleviate the cold and heat stress response of cows, and improve the content of milk protein of cows.

4. In the fattening stage of beef cattle and sheep, the use of pressed corn instead of all corn can increase the daily weight of beef cattle and sheep by about 15%-20%, improve the digestibility and absorption rate of feed, save feed costs, and reduce feed waste.

5. The use of pressed corn for beef cattle, cows and sheep can also effectively alleviate the cold stress response, resist the impact of cold on livestock, and supplement energy to livestock.

6. Feeding breeders with corn flakes can reduce the death elimination rate and improve the hatchability and wrinkle rate.

-

7 12 2022The 4th Yinchuan international dairy industry exhibition came to a successful conclusion

-

6 20 2022Does alfalfa granule belong to feedAlfalfa granule belongs to feed. Medicago sativa granules, commonly known as Medicago sativa granules, is a kind of feed made of Medicago sativa by granulating process after drying. Its protein content is high, which is conducive to storage, transportation and other advantages. It is generally used to feed cattle, sheep and other animals.